-90%

Product setup time

Lead Designer at Actilum

Actilum is a Barcelona-based manufacturer of custom LED lighting, known for made-to-measure solutions and strong client relationships in the retail signage sector.

Rapid growth exposed internal inefficiencies: duplicated tasks, unclear roles, and disconnected tools led to production errors, delays, and rising client dissatisfaction.

I led the creation of a unified internal platform that connected all departments through contextual workflows—cutting errors to nearly zero and eliminating overtime across teams.

January 2017 — January 2018

Product setup time

Sales-to-production errors

Replaced printed documents

Built from Agile mindset

Connected all departments

It’s early 2017, and Actilum is no longer the small workshop it was just a few years ago. The company had gone from 8 to 35 employees and was now billing several million euros annually. Growth had been fast—and so were the problems catching up with it.

The founders called a meeting with all department heads. I was there as Head of Design. The message was clear: “We’re losing control. Too many errors, too many delays, and clients aren’t as happy as they used to be. We need a solution—and fast.”

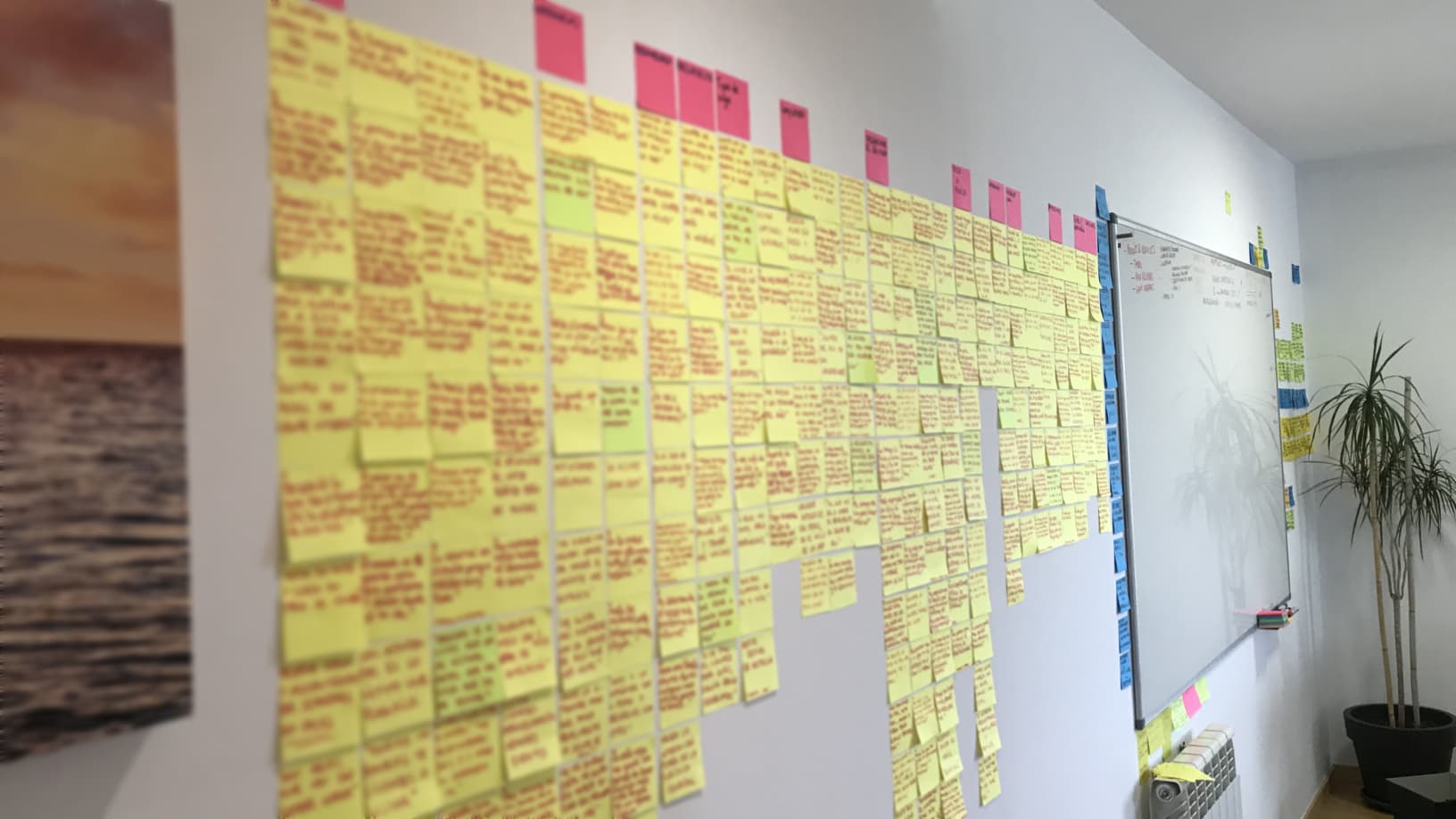

I left the meeting with a sense of urgency and an idea. I proposed hosting a cross-department workshop where each lead could openly share what was breaking in their area. It wasn’t just about listing problems; it was about creating transparency and opening the door to collaboration.

After the workshop, I met with my team to shape a plan. We knew this wasn’t just a tooling problem—it was a systems problem. We needed a process that worked across departments. But first, we needed to convince leadership we could lead this transformation from design.

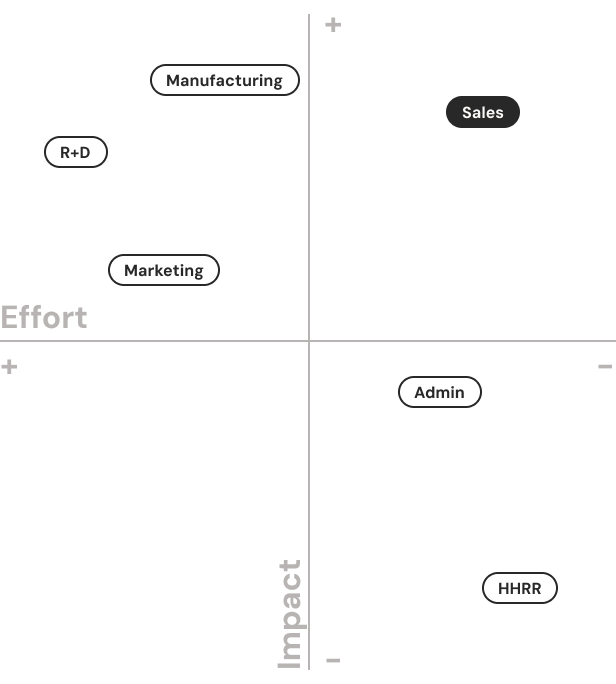

We suggested tackling the problem gradually, focusing on one department at a time. We prioritized these through strategic workshops with leadership, starting with the sales department.

We also proposed applying Service Design principles to structure the work, combining two methodologies:

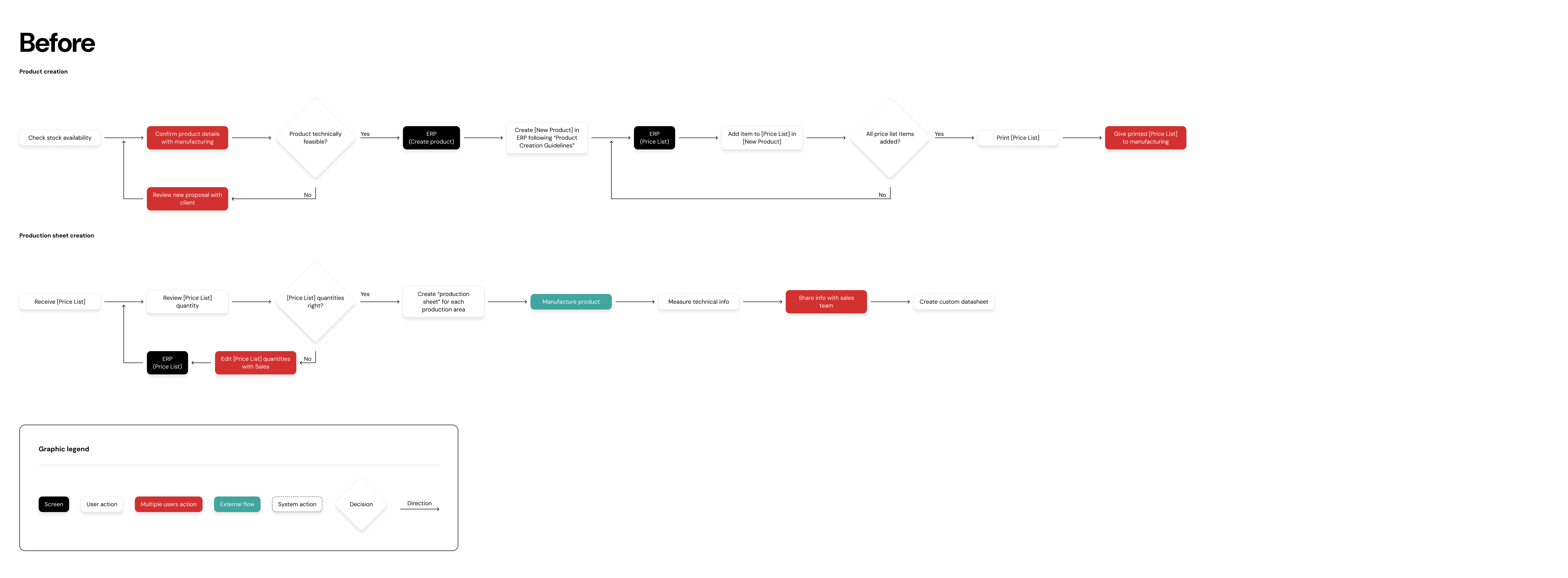

With the leadership on board, we got to work. We began by interviewing people from the sales team, but it quickly became clear we needed to expand our research across all departments. We couldn’t understand why commercial staff were spending time adding manually the price list to each product in the ERP, testing product viability, or validating shipments—tasks clearly outside their scope. What we uncovered was a web of disconnections that had normalized over time. To fix the system, we first had to understand it.

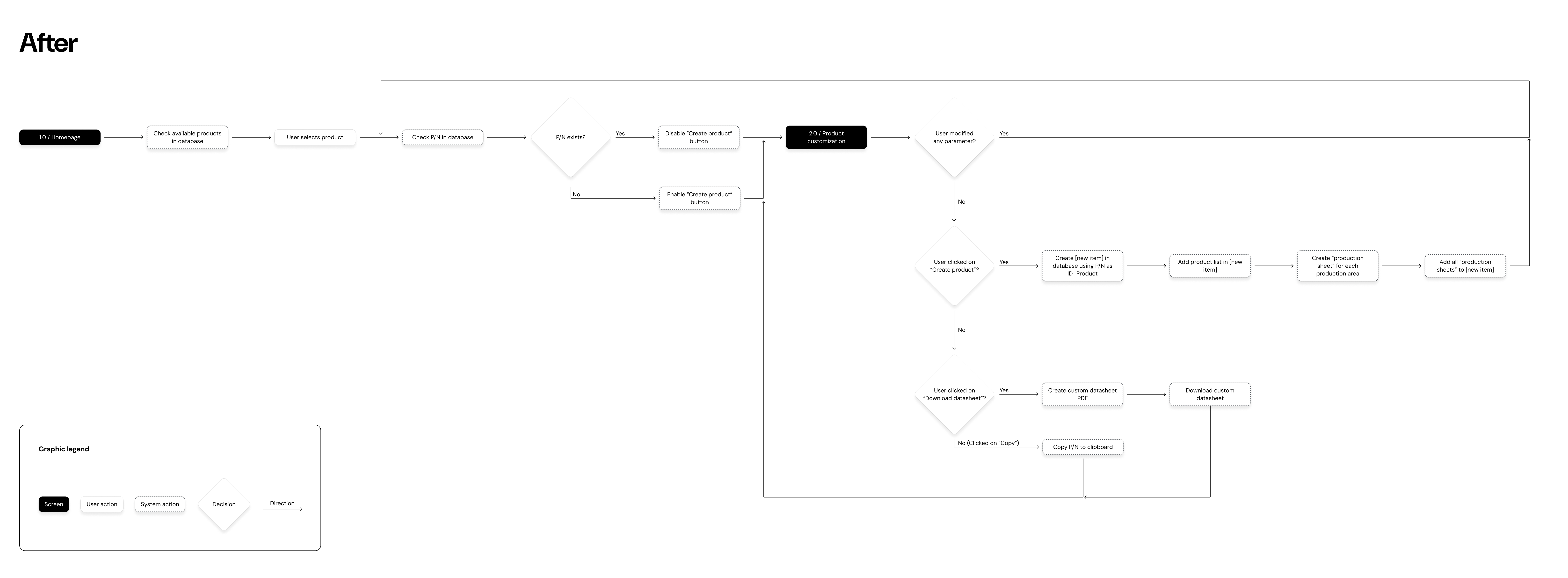

As we interviewed the sales team, it became clear that solving one area wasn’t enough. The real problem was between areas—specifically, the friction and disconnect in the handoff from sales to production. The most time-consuming and error-prone flow was what we came to call "order creation." That’s where we needed to begin.

We spent several days shadowing production and interviewing staff. The deeper issue was cultural: lack of transparency had created a lack of trust. Sales didn’t understand product limitations, and production didn’t understand the "why" behind what they were building. There was no shared language, and no shared context.

We framed the opportunity through three questions:

To improve communication and reduce costly errors, we redesigned the workflow between the sales and production departments. The goal was to ensure each team operated with clarity, responsibility, and shared context.

This new workflow became the foundation for a cross-functional system, aligning expectations between departments while increasing speed, accuracy, and trust.

We focused on:

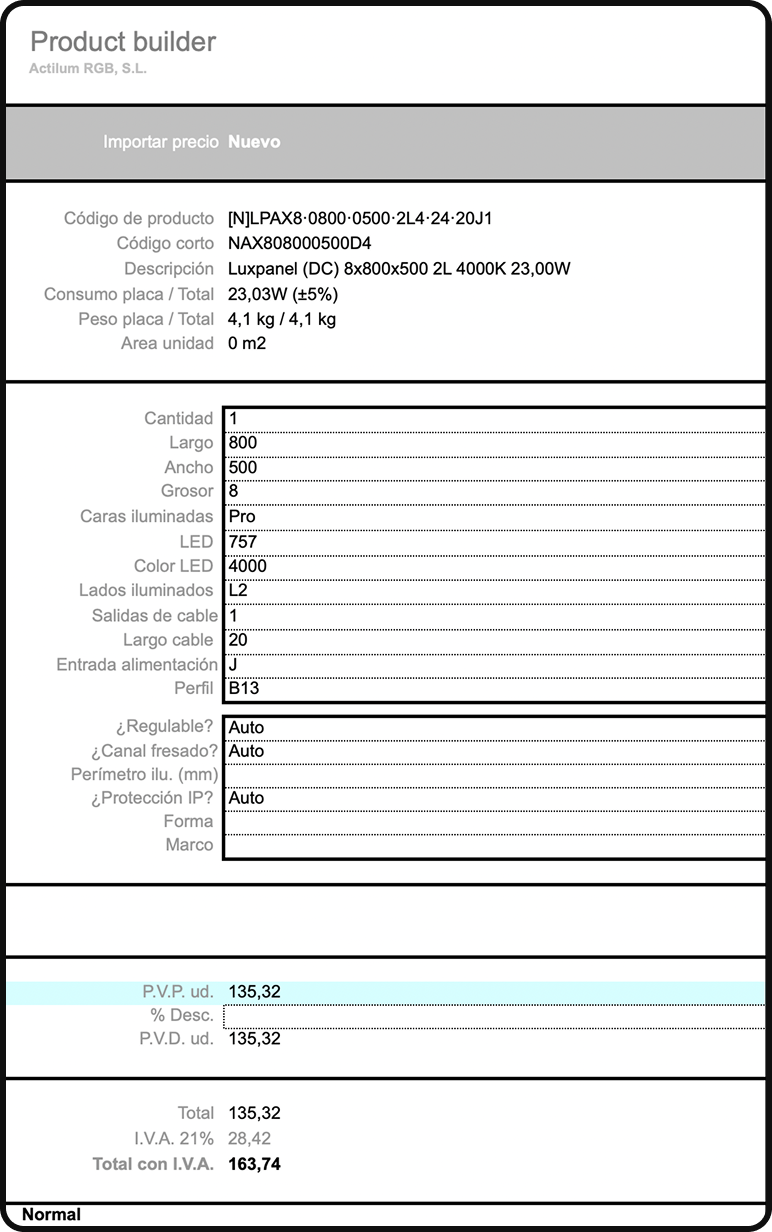

We built an Excel-based MVP called Product Builder, which served as a powerful internal tool for product configuration and production alignment. It allowed sales teams to create products step-by-step while preventing invalid combinations based on rules defined by production and R&D.

We also automated the creation of production sheets directly from the configuration, ensuring each production team received exactly what they needed, with added context about the order.

Key features included:

The MVP was a success. Product creation time dropped from 10 minutes to less than 1. Order creation was 7 minutes faster on average, thanks to clearer rules and real-time guidance.

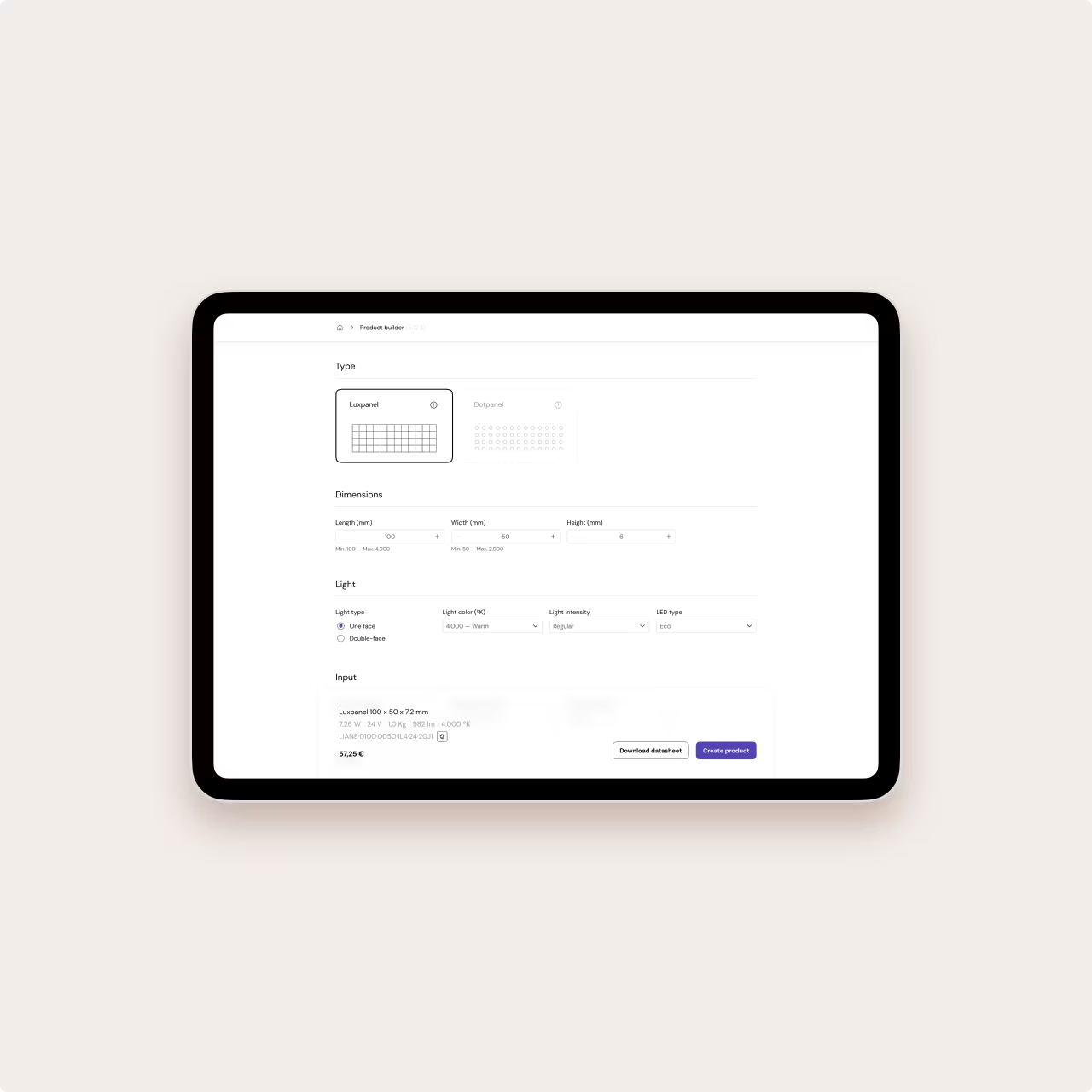

The next priorities: enable datasheet generation, connect the builder to the ERP for live pricing and stock visibility, and centralize the experience into a web-based tool.

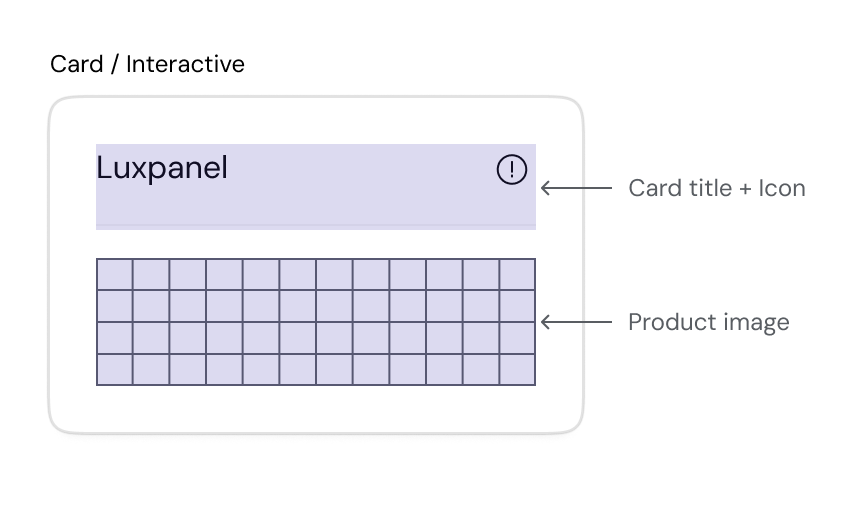

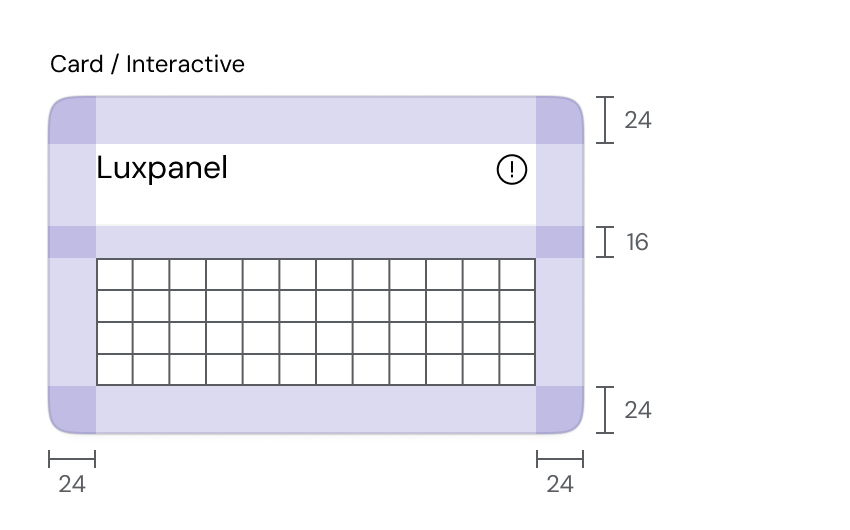

Migrating the Product Builder to a secure internal web app allowed us to:

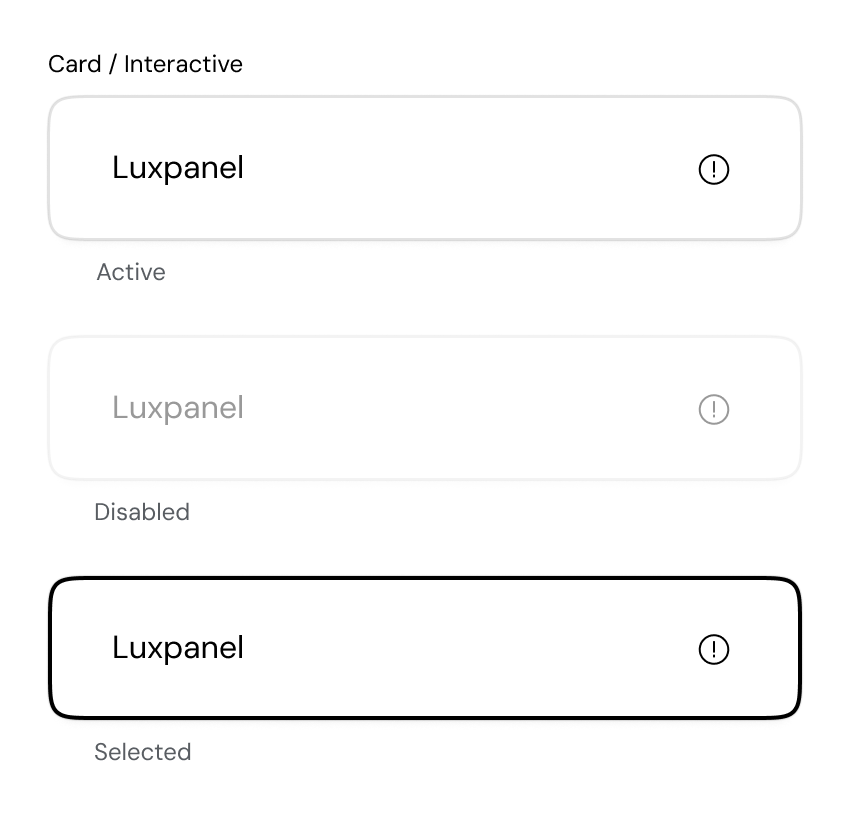

Using an atomic design system approach we decided to not reinvent the wheel in order to create our own UI elements. For the visual style, we aligned on the blend of Moon Design System tokens.

Standardizing internal workflows and eliminating guesswork between departments didn’t just improve operational efficiency — it restored client trust.

Before this project, miscommunications and production errors were visible at the very end of the chain: the client. Orders arrived late, incomplete, or incorrect, and frustration built over time. But by streamlining how teams collaborated and making processes transparent, we shifted the impact upstream — solving problems before they reached the customer.

The results were clear: